Your Industry

Your industry, Our Expertise

From steelmaking to food ovens, Refractory Partners supports every industrial sector with tailor-made refractory solutions.

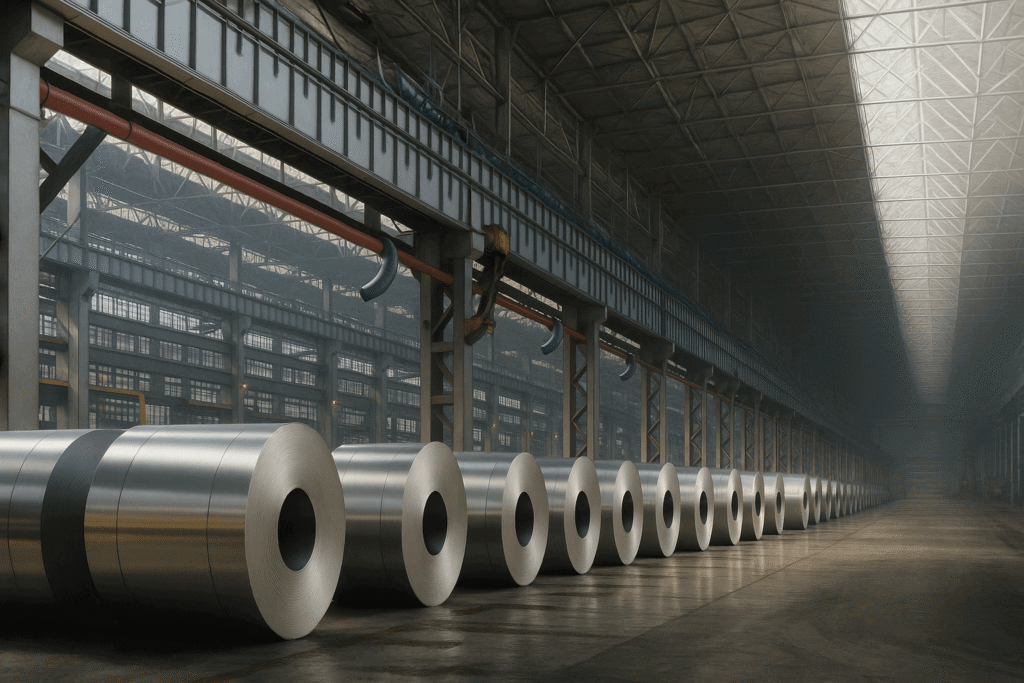

Steelmaking

We supply high-performance refractory solutions for blast furnaces, ladles, converters and tundishes. Our materials ensure superior thermal resistance and mechanical stability for continuous casting and steel refining operations.

Aluminium

Aluminium processes require precise thermal management. Our insulating materials and monolithic linings help reduce energy losses, improve safety, and extend furnace life in both primary and secondary aluminium production.

Petrochemical

Our solutions meet the demands of thermal cracking, reforming and gasification units. We provide corrosion-resistant linings adapted to high temperatures and chemical stress for improved reliability and reduced downtime.

Cement

Cement kilns and lime furnaces require refractory linings capable of withstanding abrasion, alkali attacks, and intense heat. Our tailored linings offer long-lasting protection to support high clinker quality and energy efficiency.

Power Generation

From biomass to waste-to-energy plants, our refractory solutions enhance the performance and durability of combustion chambers, boilers and heat exchangers while ensuring compliance with environmental standards.

Glass

Glass production involves sustained high temperatures and thermal shock risks. We deliver refractory blocks, insulation and accessories adapted to furnaces, regenerators and forehearths, optimising glass quality and energy use.

OEMs

We support OEMs by supplying standard and custom-made refractory parts—shapes, modules, mastics and insulating materials—ready to integrate into any industrial furnace design.

Incinerators

We offer refractory systems designed to withstand corrosion, slagging, and thermal shocks in incinerators and gasification plants. Our materials help meet strict environmental and energy recovery standards.