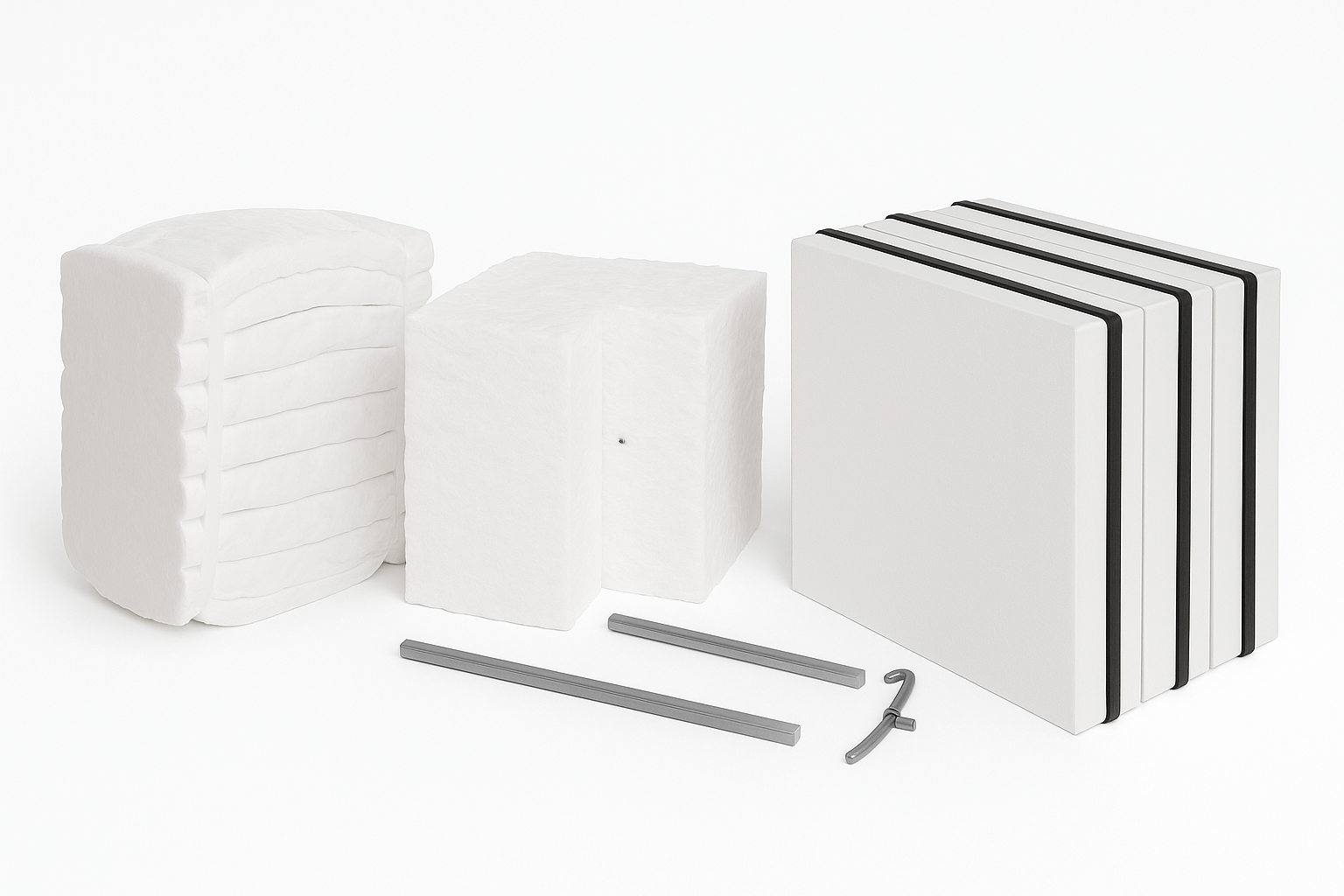

Our unique Pyro-Bloc®, Pyro-Fold™ and Pyro-Stack™ Modules provide performance to the hot face lining for industrial furnaces, boilers, and kilns.

Trusted and reliable performance, our Pyro-Bloc Modules, a monolitihic design made from our Pyro-Log and our blanket module systems, Pyro-Fold and Pyro-Stack Modules, modules from Thermal Ceramics have been chosen and specified for decades.

Our range comprises of the following fibre grades:

- Superwool® Low Biopersistent Fibres (LBP)

- Alkaline Earth Silicate Fibre (AES):

- Superwool Plus classification temperature of 1200°C (2192°F)

- Superwool Prime classification temperature of 1300°C (2372°F)

- Potassium Alkaline Silicate (PAS)

- Superwool XTRA classification temperature of 1450°C (2600°F)

- Alkaline Earth Silicate Fibre (AES):

- Refractory Ceramic Fibres:

- Kaowool® classification temperature of 1260°C (2300°F)

- Cerablanket® classification temperature of 1315°C (2400°F)

- Cerachem® classification temperature of 1426°C (2600°F)

- Polycrystalline Wool Fibres for Pyro-Stack Module designs

- Maftec® classification temperature of 1600°C (2912°F)